Our dedicated team of skilled professionals combines their expertise with the latest advancements in engineering, ensuring that each project is executed with the utmost precision and attention to detail.

Lance Swan

Prototyping is an indispensable phase in the product development journey, driving innovation and ensuring successful outcomes. During this iterative process, various iterations of the design are created, tested, and refined, enabling critical evaluation of form, function, and feasibility. Prototyping offers invaluable opportunities to identify and address potential design flaws, optimize performance, and gather valuable user feedback early on. Ultimately, prototyping fuels creativity, accelerates problem-solving, and empowers teams to deliver exceptional products that meet customer needs and exceed expectations.

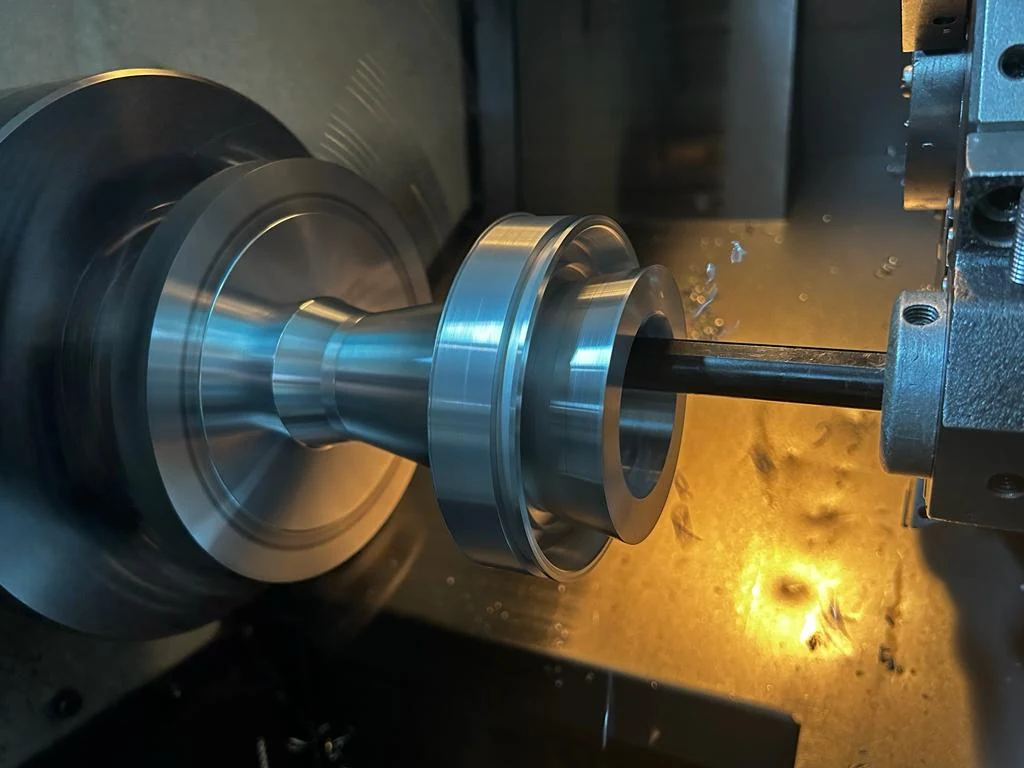

CNC turning encompasses a manufacturing method in which computer-controlled machines meticulously fashion cylindrical components by subtracting material from a rotating workpiece. This process employs a cutting tool aligned with the workpiece’s rotational axis, enabling it to eliminate material as it traverses along the workpiece’s length. Widely employed in automotive, aerospace, medical device manufacturing, and various other industries, CNC turning machines provide numerous benefits compared to manual turning. These advantages include enhanced production speed, heightened precision, and the capacity to craft intricate designs.

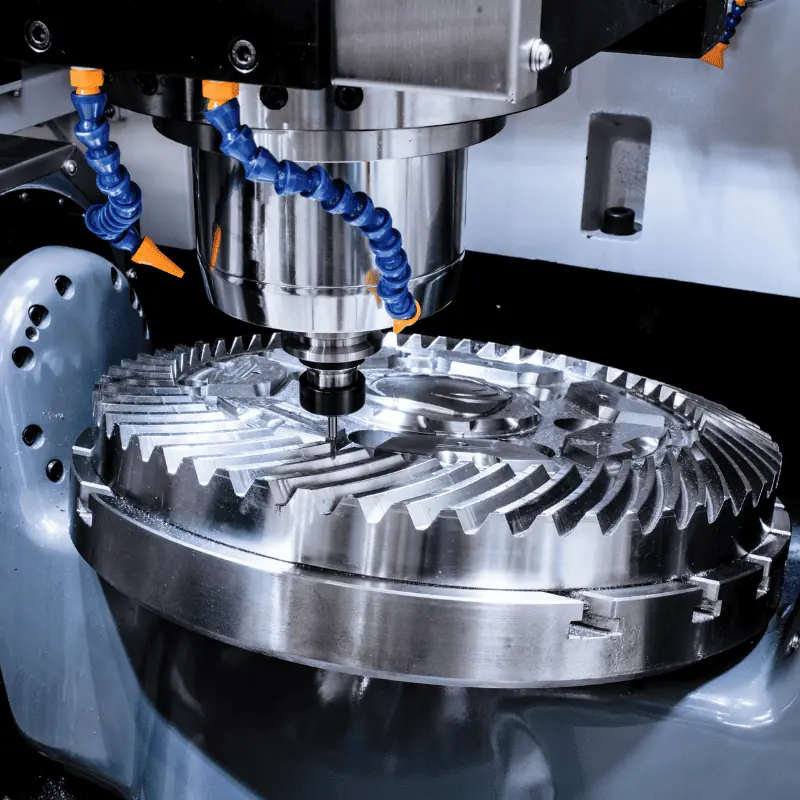

At our facility, we proudly utilize cutting-edge high precision three-axis machining centres that redefine the realm of precision manufacturing. Equipped with advanced capabilities, these machines empower us to seamlessly produce intricate components with exceptional accuracy and tight tolerances.

With our relentless commitment to delivering excellence, we leverage the full potential of our three-axis machining centres to bring your most complex designs to life. Our team of skilled engineers and operators expertly navigate the intricacies of these advanced machines, ensuring that each piece meets the highest quality standards.

CAM automatics represent a game-changing advancement in manufacturing technology, revolutionizing the production process with their remarkable precision and efficiency. These automated systems, integrated with computer-aided manufacturing (CAM) software, streamline the creation of complex components with unparalleled accuracy. With their ability to perform intricate operations swiftly and reliably, these machines optimize productivity and reduce production time.

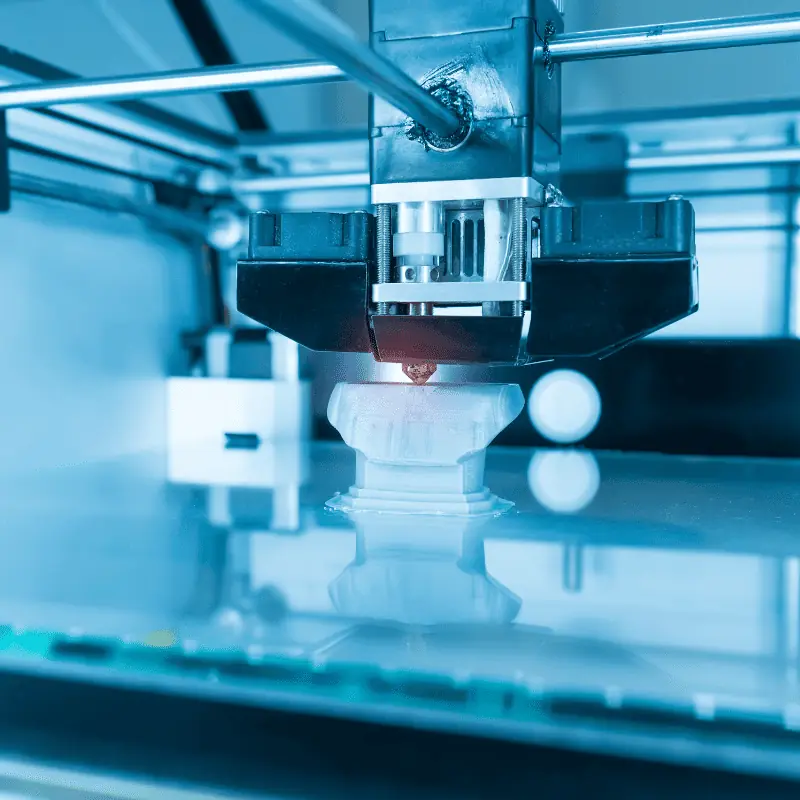

3D printing is a revolutionised solution for engineers and designers seeking to develop intricate and precise 3D models of mechanical parts and assemblies. It is versatile and accurate, and empowers users with a comprehensive suite of powerful tools and features, making the creation of complex designs a seamless and efficient process.